Prevent spills and damage

How Next Vision Copilot helps

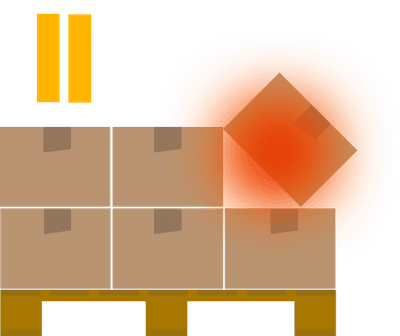

Spot issues before they cause downtime

Copilot spots issues early,even the ones no one has ever seen before

Automatic Production Pauses

Pause production before issues escalate, with clear guidance on potential problem areas

See Root Causes Clearly

No more guesswork. Review automatically grouped recordings and data to pinpoint specific improvement opportunities.

How the Copilot pays for itself

80%

Reduction in crashes

>95%

Operators experience less stress

3+

Extra hours of uptime per week

What the Commissioning Assistant does for you

- The system immediately documents any imperfections that can arise when integrating a new system. This makes it much easier to communicate with your supplier about any issues.

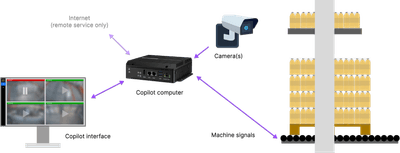

- Works with your existing camera setup or via a camera from us with simple mounting options.

- Commissioning new machines or lines is significantly less stressful when deviations are stopped and documented right away.

Schedule a Demo

Talk to our experts to learn more about how Next Vision Copilot can you

Frequently Asked Questions

Next Vision Copilot monitors your production like a skilled operator, learning how processes run and intervening when needed. It provides an overview rather than high-speed product inspections.

You have full control—footage never leaves your facility unless you choose to share it.

Next Vision Copilot does not collect or process personal data, ensuring full compliance with privacy regulations.

Installation depends on your setup. Once activated, Copilot immediately starts learning and can take on more responsibilities over time.

We currently focus on packaging and palletization but are expanding. Contact us to explore solutions for your workflow.

We're happy to help! Contact us via email or phone with any additional questions.